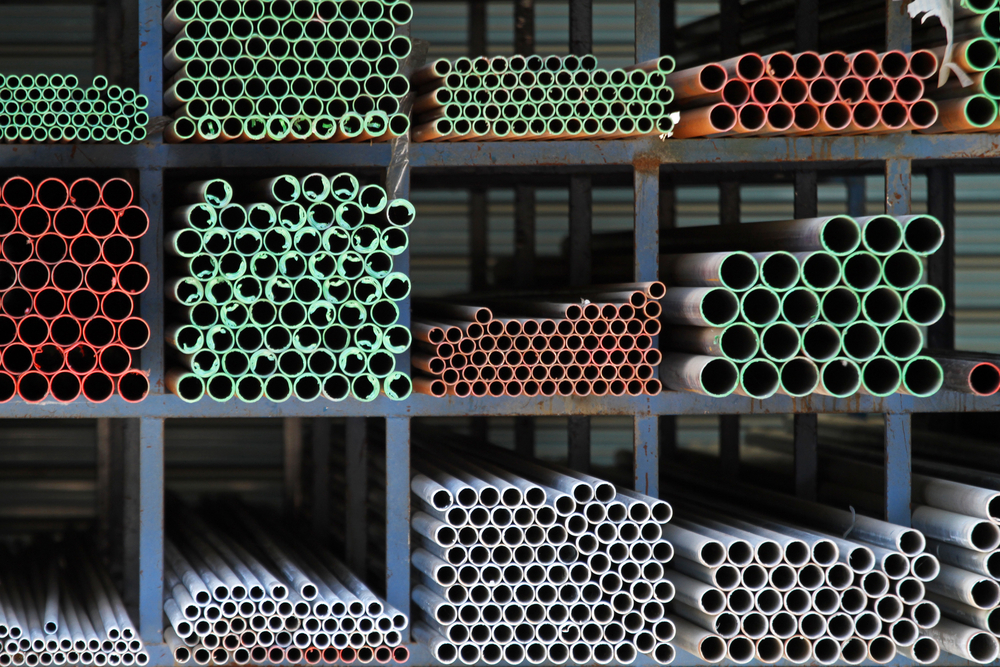

What we distribute and supply

Seamless

The seamless steel pipe manufacturing process starts with a solid, round steel billet. This billet is then heated to great temperatures and stretched and pulled over a form until it takes the shape of a hollow tube. As other steel pipe suppliers will tell you, there are three great advantages to making a pipe in this way.The greatest advantage of seamless steel pipes is their increased ability to withstand pressure. The weakest point in a welded steel pipe is the welded seam. But because a seamless steel pipe has not been welded, it doesn’t have that seam, making it equally strong around the entire circumference of the pipe.

Longitudinal Submerged Arc Welded (LSAW)

LSAW, as the name suggests, are steel pipes that have a straight weld running down the length of the pipe. These pipes are designed to withstand high pressure and temperature which is a common requirement for oil and gas industries. These pipes can have thickness of 1 inches or greater, which makes them very strong. The pipes are also produced in Conformity to ASTM and API grades and specifications.. .